Whether confectionery, delicatessen or convenience products – our platforms are used where hygiene, stability and safety are crucial.

With over 30 years of manufacturing experience, we develop stable, custom-fit platform solutions for dry and wet areas.

Steel platforms for drying rooms (e.g. Haribo, Melitta, Brüggen Lübeck)

Stainless steel platforms (1.4301) for delicatessen and wet areas with the highest hygiene requirements

We think platform construction from a production perspective.

As a machine manufacturer with our own food technology, we know exactly what is important in practice – space, safety, cleanability and load-bearing capacity.

That’s why we plan and manufacture stages that:

- are precisely matched for multihead weighers, filling machines and conveyor systems

- can be integrated smoothly into existing lines

- remain stable, safe and hygienic for years, even under full load

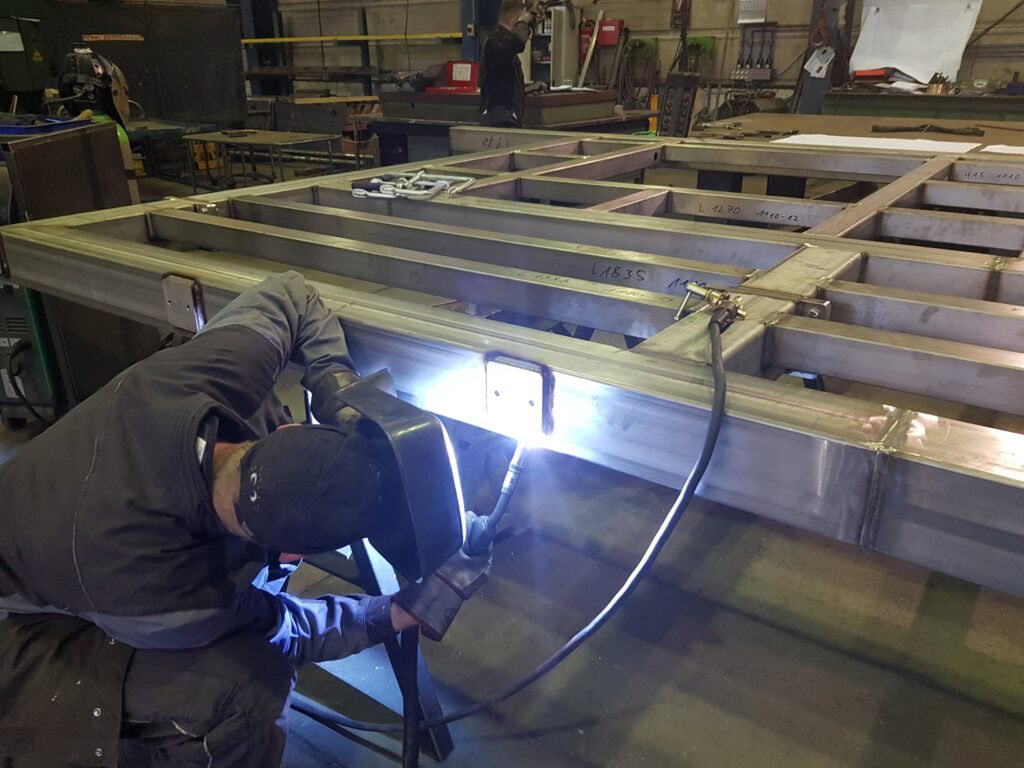

- And most importantly, our certified welders guarantee quality that stands the test of time - safe, documented and auditable.

Your contact for customized stages

Are you planning a stainless steel container project?

We develop hygienic, stable and custom-fit solutions – and support you from the idea to the finished implementation.

Enquire now without obligation

Frequently asked questions

In the dry area we use steel, in the wet area only stainless steel of at least grade 1.4301.

Yes, depending on the project, we deliver the stage ready for assembly or set it up directly on site with experienced partners.

What are the benefits of certified welding?

Answer: Our certified welders ensure documented quality, maximum stability and compliance with all industry-specific hygiene requirements.